I Description:

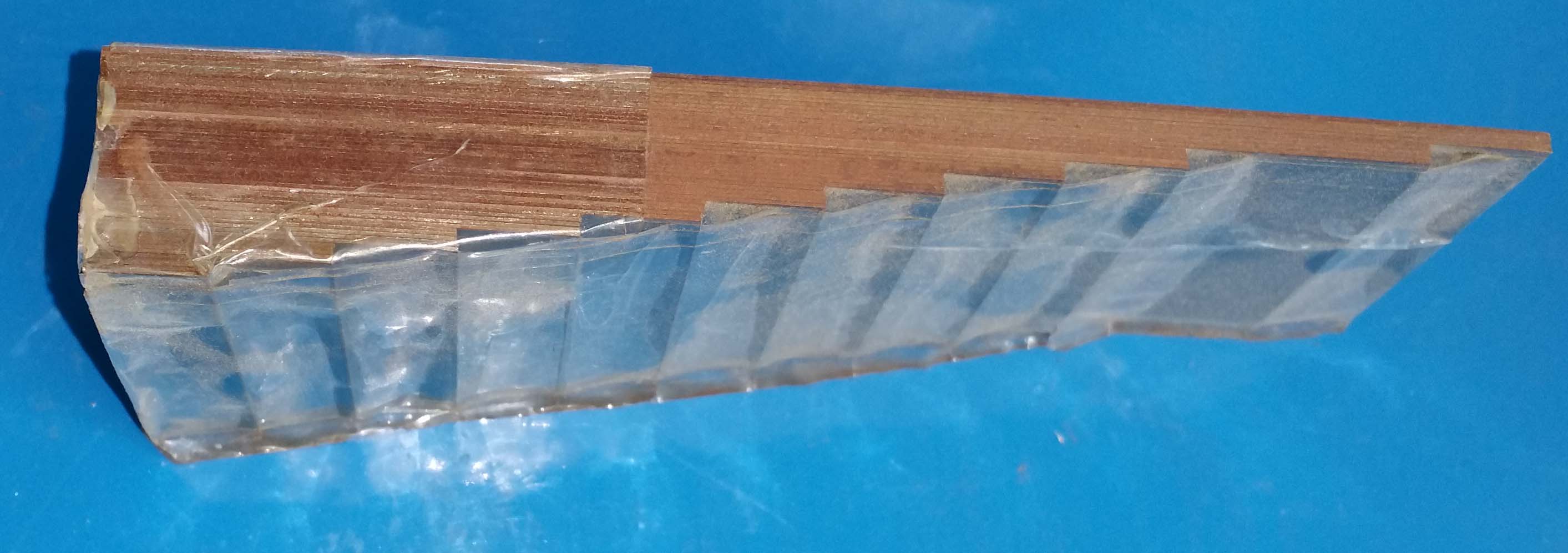

This machine is specially designed for cutting silicon steel coils into silicon strips for transformer cores, welding machine cores, and reactor cores.

II Production flow: decoiling, servo feeding, punching & cutting, collecting.

III Buildup of the machine:

3.1 Inverter-controlled decoiler:

- Motor power: 2.2kW

- Max. coil weight:

- Max. coil width: 300mm

- Coil inner diameter: 480

- Coil outer diameter:

3.2 High speed feeding device

- Servo motor driving: Delta servo motor, 2kW

- Feeding precision: +/

- Feeding speed: max.

- Feeding roller material: special mould steel in high hardness

3.3 Punching device

- High speed punching, 50-100 times per minute

- Hole precision: +/

- Punching motor power: Delta servo motor 2kW

- Punching die: carbide alloy, life more than 1,200,000 times before grinding, more han 20 times grinding

- Hole position is pre-set on the touch screen

- Max. hole numbers: 12

- Max. hole diameter: 8

3.4 Straight Cutting device

- High speed cutting, 50-100 times per minute

- Cut-to-length tolerance: +/

- Cutting motor power: inverter controlled motor 2.2kW

- Cutting blade: carbide alloy, life more than 2,000,000 times before grinding, more than 20 times grinding

- Quantity and length are pre-set on the touch screen

3.5 Run-out table: prepared by Buyer, for collecting cut pieces

3.6 Control system

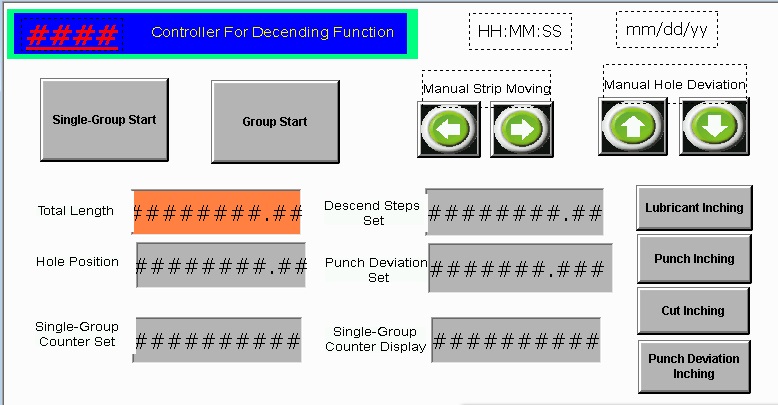

- Delta PLC

- Delta touch screen

- Quantity, length, speed, hole numbers, hole positions can be pre-set on the touch screen

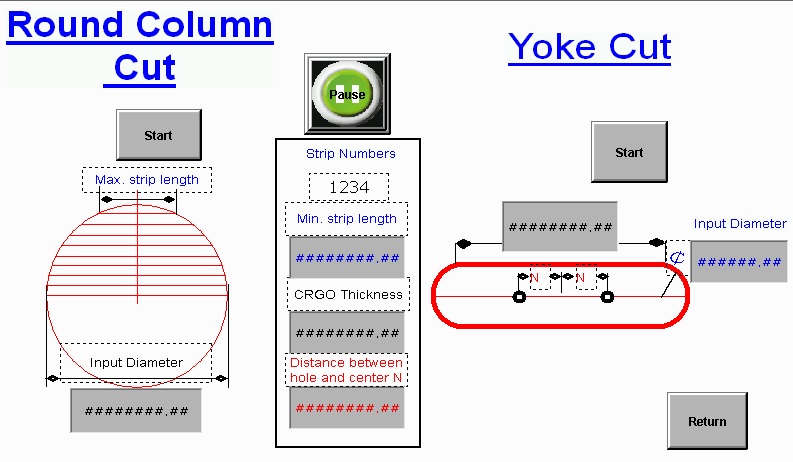

- Special round column cutting function included:

- Laminations can be cut by above flexible programs:

IV Main technical data

|

Item |

Data |

|

Suitable silicon steel strip width |

30-300mm |

|

Max. silicon steel thickness |

0.6mm |

|

Cut to length |

1-999999mm |

|

Cut to length tolerance |

+/-0.02mm |

|

Suitable hole diameter |

8-25mm |

|

Hole position tolerance |

+/-0.02mm |

|

Punching hole numbers |

0-12 |

|

Burr height |

Less than 0.02mm |

|

Servo feeding speed |

Max. 100m/min |

|

Cutting speed |

50-100 cuts per minute |

|

Dimension |

About 1200 x 1600 x 1200mm (main machine) |

|

Weight |

About 900kg |