I Summarize

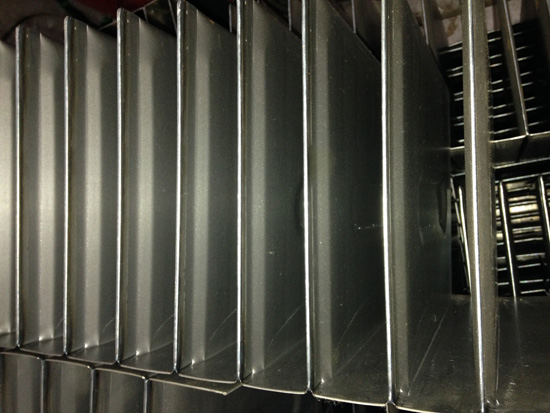

This is specially for welding the transformer corrugated tank, controlled by PLC, cylinder clamping to ensure the welding quality. Automatic feeding, welding by one time.

II Main features

- PLC control, full automatic, automatic conveying, automatic clamping, automatic welding

- Welding movement is by servo motor

- Argon arc welding, very tight welding result, very clean and smooth finished welding surface

- Very easy and simple operation on touch screen

III Main technical data

|

Item |

Data |

|

Suitable fin size |

Max. 1300 x 400mm (can be specially ordered) |

|

Suitable fin thickness |

1-1.5mm |

|

Suitable space inside fin |

5-8mm |

|

Suitable distance between fins |

40-80mm |

|

Welding speed |

When fin height is 100mm, 3 fins per minute; When fin height 200mm, 2 fins per minute (such speed is also based on the fin thickness) |

|

Argon arc welding machine (TIG) |

Two pieces, welding current 10-300A |

|

Compressed air needed |

0.4MPa |

|

Chain driving motor power |

3.2kW |

|

Machine weight |

About 4000kg |

|

Dimension |

About 2300 x 3200 x 1800mm |

|transformer corrugated tank fin welding machine|transformer corrugated tank fin welding machine|transformer corrugated tank fin welding machine|

IV Main configuration

- Electric control, Schneider from Germany

- Welding torch, 2 sets, Sanrex from Japan

- Pneumatic cylinder: 6 sets, from China

- Step motor: Delta from Taiwan

- PLC: Panasonic from Japan

- Touch screen: Panasonic from Japan

- Sensor: ROKO from China

|transformer corrugated tank fin welding machine|transformer corrugated tank fin welding machine|transformer corrugated tank fin welding machine|