This machine is specially designed for winding wireless charging coils full automatically, suitable for strand wires and silk-covered wires.

II Main features of CNC wireless charging coil winding machine

- Hot air bonding

- Full automatic 4-axis servo motor control

- Wire feeding device adopts SMC rodless cylinder plus HIWIN linear guide

- World famous brand PLC control system

- Full seal protection enclosure, clean and good safety

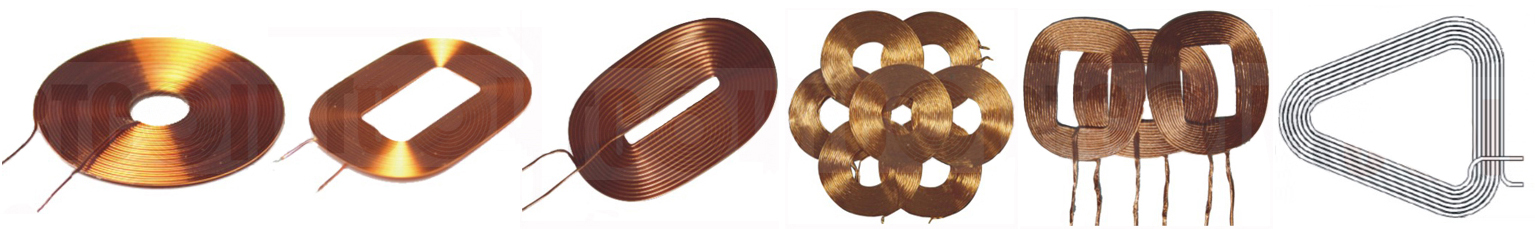

III Photos of wireless charging coils can be produced by CNC coil winding machine:

IV Main technical data of CNC wireless charging coil winding machine:

|

No. |

Item |

KXJ-064 |

|

1 |

Number of spindles |

4 |

|

2 |

Winding wire section range |

1-8mm2 |

|

3 |

Suitable wireless charging coils |

Both transmitting and receiving coils |

|

4 |

Bonding method |

Hot air blowing |

|

5 |

Finishing lead position |

Arbitrary |

|

6 |

Flying spindle speed |

0-3000 rpm |

|

7 |

Winding spindle speed |

0-3000rpm |

|

8 |

Max. production speed |

2 pcs/min |

|

9 |

Winding direction |

Clockwise / anti-clockwise |

|

10 |

Winding spindle motor (X-axis) |

AC 400W, servo |

|

11 |

Flying spindle motor (Y-axis) |

AC 400W, servo |

|

12 |

Finishing lead motor (Z-axis) |

AC 400W, servo |

|

13 |

Tail stock motor (A-axis) |

AC 400W, servo |

|

14 |

X-axis setting range |

0 - ±999999C359º |

|

15 |

Y-axis setting range |

0 - ±999999C359º |

|

16 |

Winding spindle stop precision |

0º |

|

17 |

Winding set resolution ratio |

0.1º |

|

18 |

Beginning lead length |

Min. 10mm, max. 30mm |

|

19 |

Finishing lead length |

Min. 10mm, max. 50mm |

|

20 |

Hot air heating element power |

AC 1600W |

|

21 |

Electric power supply |

Single phase 210~230V, 50Hz |

|

22 |

Compressed air pressure |

0.5~0.7MPa |

|

23 |

Machine dimension |

900 x 530 x 1450mm |

|

24 |

Machine weight |

250kg |