- Full automatically, from decoiling to stacking, only three operators are needed

- Good & reliable punching/shearing power: imported hydraulic servo control, quick speed, low noise and long life

- Good & reliable feeding power: big torque AC servo motor, quick responding, high positioning precision, low noise, low braking heat loss, long life

- Track positioning: servo motor pulling ball screw, linear guide positioning, quick, accurate, convenient; automatically memberizing track width.

- Movement control: adopts advance PCC controller, Ethernet Powerlink communication technology, massly reduces wire connection and so raise the reliability, stability and realtime ability of the system; remote control and diagnosis

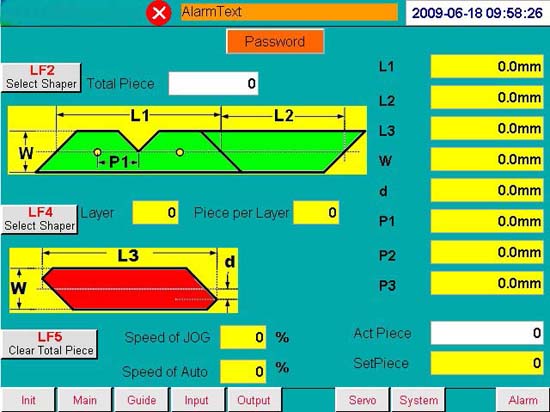

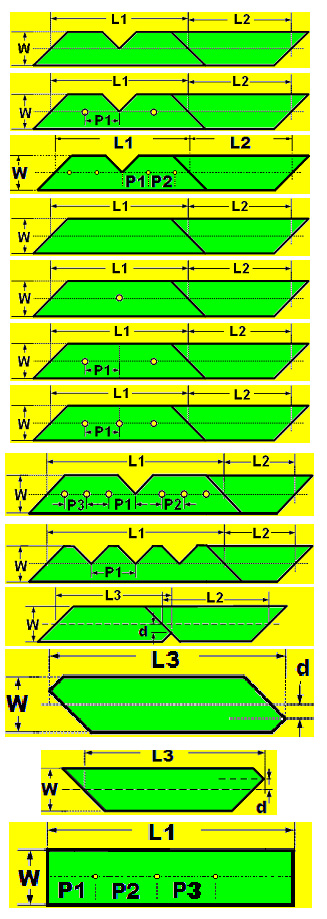

- Simple & intuitive operation: choose strip shape and input sizes and dimensions on the touch screen

- Adopts inverted-support collecting method which can collect and order 5m long strips and reduces the vibration, thus reduces affects to magneting performance of CRGO strips during processing.

- Equipped with Step-Lap function, step-lap quantity can be 7.

- Imported world famous brand parts, such as linear rail, ball screw, bearings, etc., assure machine long life

- New improved COLUMN-STACKING function, five columns (two yokes, two side limbs and one center limb) can be stacked automatically. Stacking precision +/-0.3mm.

3.1 Double-head hydraulic expansion decoiler, inverter control, automatic decoiling

3.2 Automatic servo feeding system

3.3 Servo controlled O-shape punching press

3.4 V-shape punching press, servo controlled transverse feeding

3.5 45°electric shear, servo control, central positioning

3.6 135°electric shear, servo control, central positioning

3.7 Track positioning device

3.8 Flat belt transmitting device

3.9 Collecting system (servo positioning, magnet absorbing)

3.10 Double-layer unloading car

3.11 Electric control system, and control box

3.12 Pneumatic system

IV Main technical data:

|

Code |

BHX-400 |

BHX-600 |

BHX-900 |

|

CRGO coil width |

40-440mm |

60-640mm |

80-920mm |

|

Cutting length |

300-2500 |

400-3500 |

500-5000 |

|

CRGO thickness |

0.23-0.35 |

0.23-0.35 |

0.23-0.35 |

|

Cut-to-length precision |

±0.2mm |

±0.2mm |

±0.2mm |

|

Burr height |

≤0.02mm |

≤0.02mm |

≤0.02mm |

|

Cutting angle precision |

±0.025° |

±0.025° |

±0.025° |

|

Feeding Speed |

0-240m/min |

0-240m/min |

0-240m/min |

|

One cut duration |

≤230ms |

≤240ms |

≤250ms |

|

Cutting tool life |

1,200,000 times before grinding |

||

|

Punching tool life |

500,000 times before grinding |

||

|

Max. step-lap stroke |

25mm |

25mm |

25mm |

|

Step-lap quantities |

1, 2, 3, 4, 5, 6, 7 |

||

|

Positioning method |

Central line positioning |

||

|

Strip collecting method |

Inverted support type, auto stacking |

||

|

HMI |

10.4'' VGA color TFT display and 44 function keys and 20 system keys |

||

|

Total electric power |

25kW |

30kW |

35kW |

|

Line occupation (LxWxH) |

15m×5m×2m |

18m×5.5m×2.5m |

22m×6m×2.5m |