|

Function |

Description |

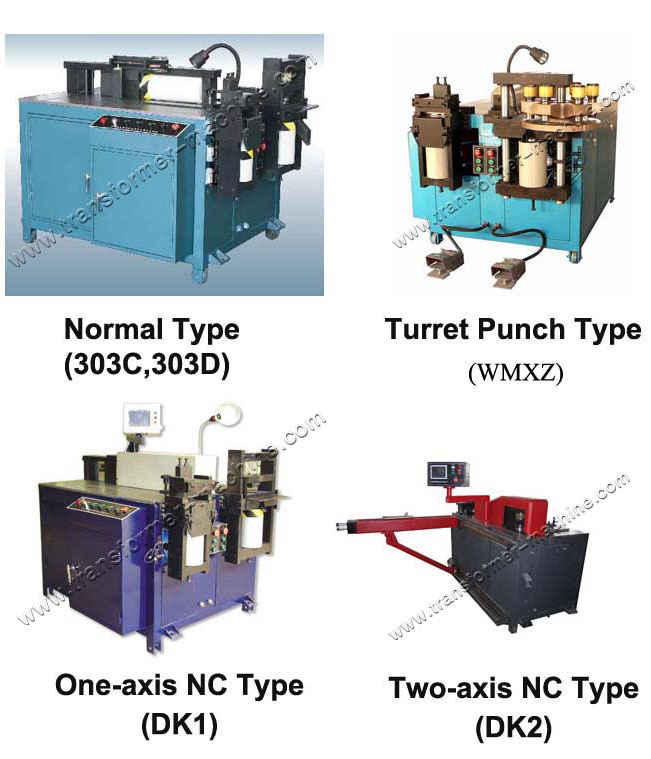

WMX WMX-303D

|

WMXZ WMXZ-303D |

NCMX-303DK1 |

NCMX-303CK2 |

|

Punching |

Max. punching pressure(KN) |

300 |

|||

|

Hole diameter (mm) |

ф4.3~ф25 |

||||

|

Max. thickness (mm) |

12 |

||||

|

Max. width (mm) |

150 |

||||

|

Cutting |

Max. thickness (mm) |

12 |

|||

|

Max. width (mm) |

150 |

||||

|

Bending |

Max. bending pressure (KN) |

300 |

|||

|

Max. width (mm) |

150 |

||||

|

Max. thickness (mm) |

12 |

||||

|

Vertical bending |

Max. width (mm) |

100(10㎜ copper) |

|||

|

Min. bending angle |

90° |

||||

|

Embossing |

√ |

√ |

√ |

√ |

|

|

Pressing tie-in |

√ |

√ |

√ |

√ |

|

|

Twisting |

√ |

√ |

√ |

√ |

|

|

Dimension (L x W x H, mm) |

1300×1000×900 |

1300×1000×900 |

1300×1000×900 |

1700×2200×1550 |

|

|

Weight (kg) |

1.1/1.2T |

1.3/1.4T |

1.2T |

1.2T |

|

|

Main motor power |

|

||||